FEATURE

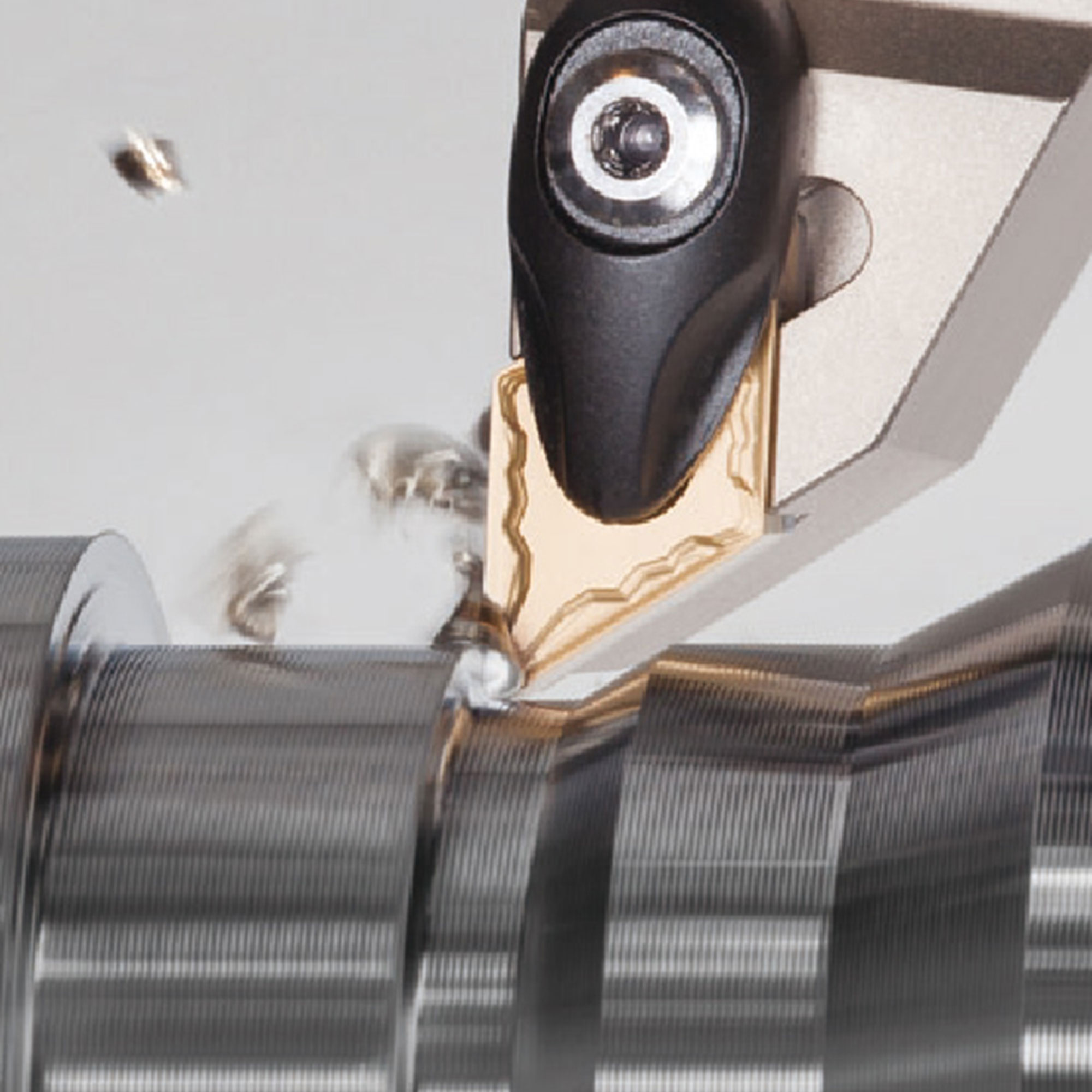

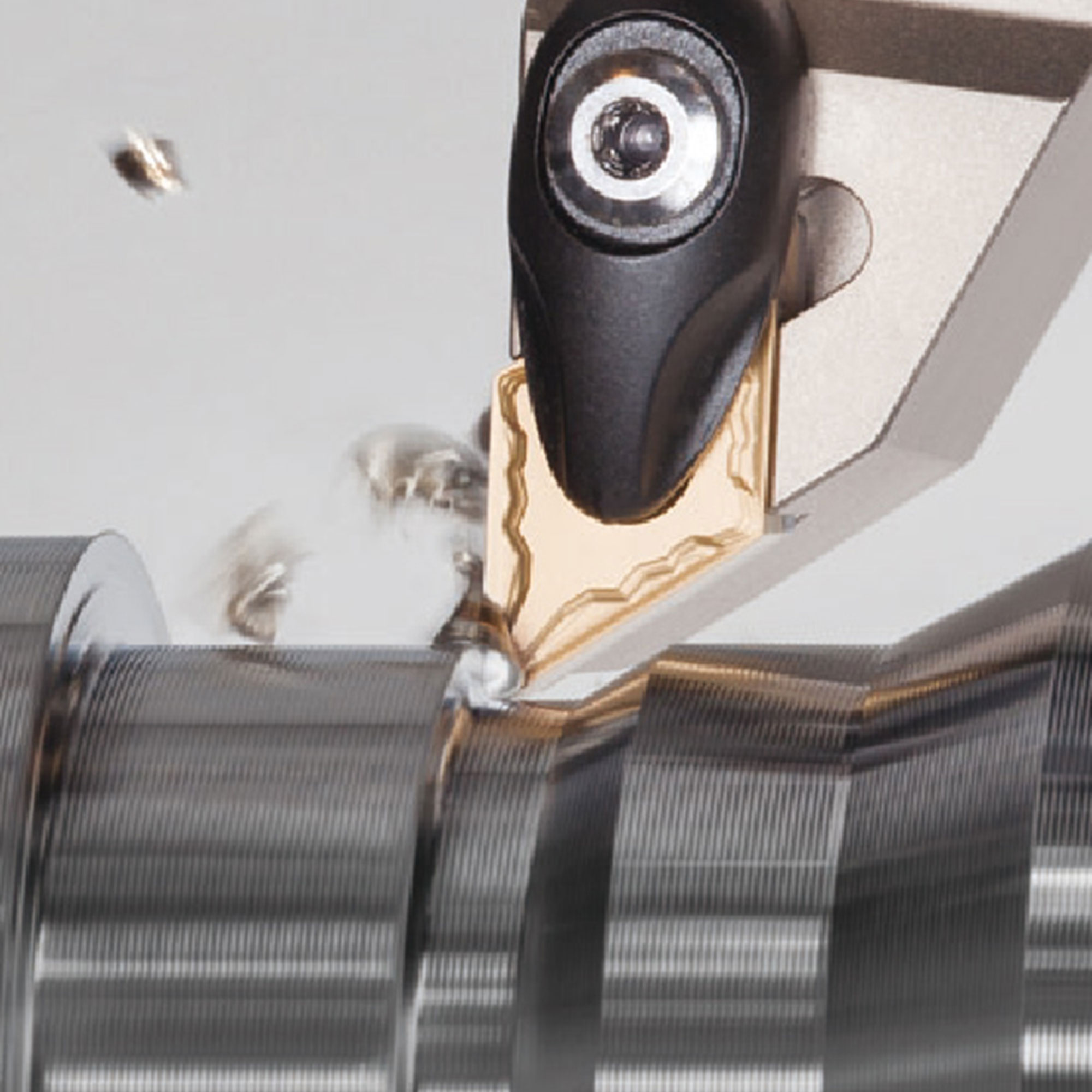

1. Extreme Durability

Features high-density tungsten carbide substrate with advanced PVD/CVD coatings (TiAlN/TiCN), delivering exceptional wear/heat resistance and over 50% longer tool life, ideal for continuous cutting of stainless steel and alloy steel.

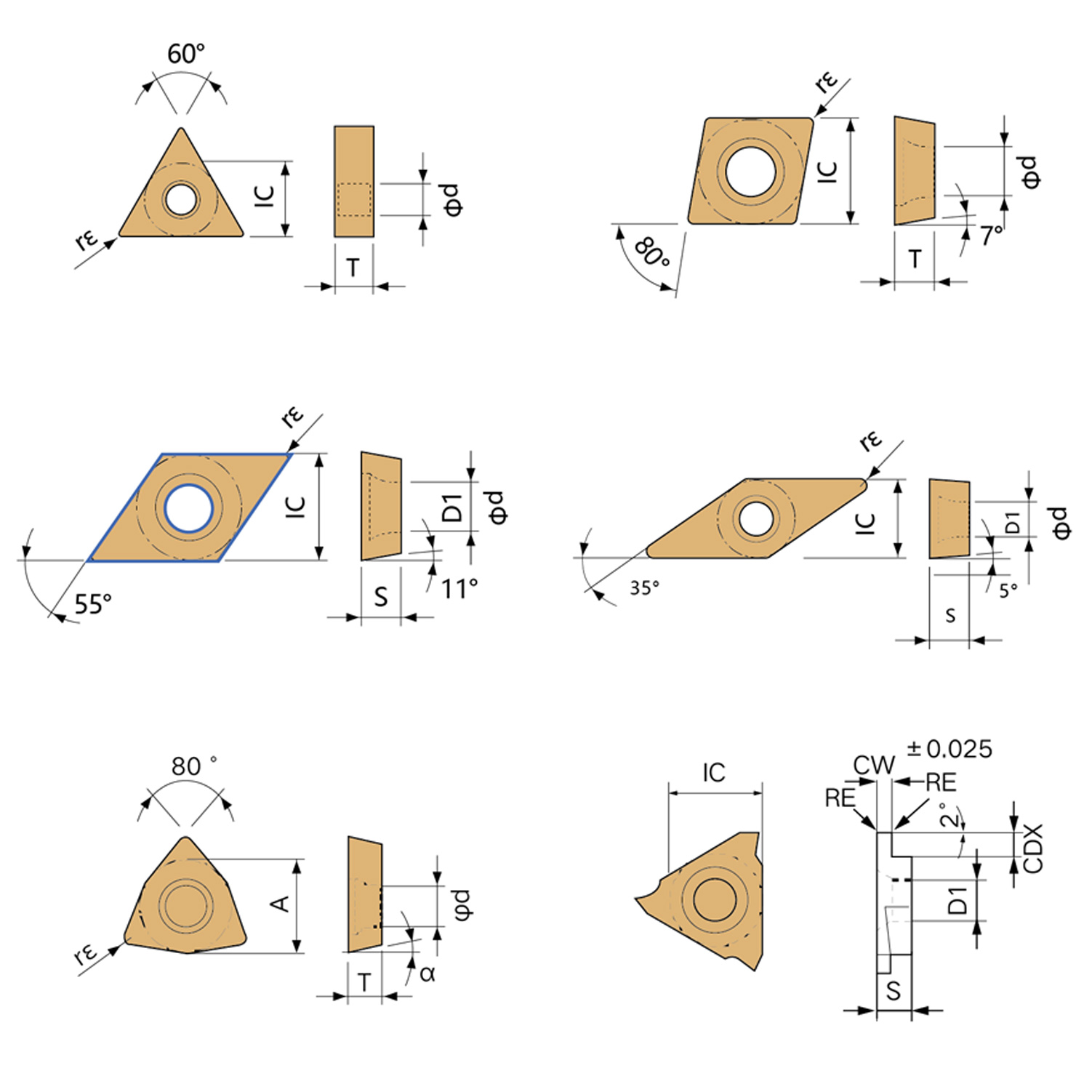

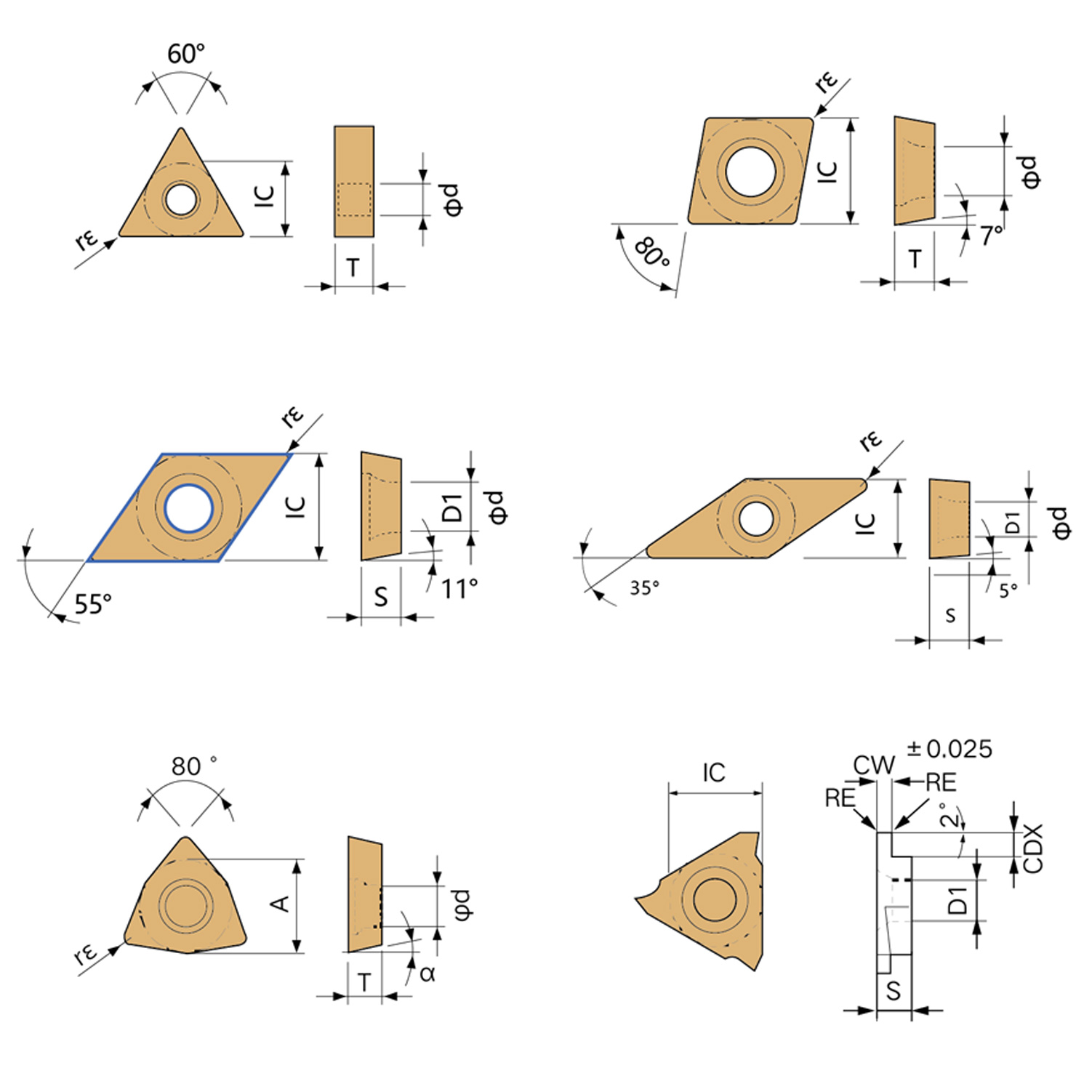

2. Precision & Efficiency

The 55° diamond design provides 8 cutting edges per insert with optimized chipbreakers (MF/MS options), enabling 0.01mm machining accuracy and surface finish of Ra≤0.8μm.

3. Universal Adaptability

ISO 9001 certified for machining steel, cast iron, and heat-resistant alloys. Supports turning, facing, and profiling operations on all major CNC lathes and automated production lines.

© Vulcan Industry | All Rights Reserved | Design by winnet.cc

© Vulcan Industry | All Rights Reserved | Design by winnet.cc